Shenzhen Explosive Certificate Label: Copper Spot Self-Adhesive Sticker for Inspection & Digital Identification

In high-stakes industrial environments, a single overlooked detail can spark catastrophe. Imagine a routine inspection at an offshore oil rig where a faded certification label goes unnoticed—leading to the use of non-compliant equipment in a volatile atmosphere. The result? A chain reaction culminating in explosion, injury, and operational paralysis. This isn’t fiction; it’s a stark reminder of how fragile safety systems can be when trust is placed in temporary or unreliable identification.

When Safety Meets Intelligence: How Shenzhen’s Explosion-Proof Labels Are Redefining Industrial Identity

In response to such risks, a quiet revolution has taken root in the heart of China’s innovation corridor—Shenzhen. Here, engineering precision meets digital traceability in the form of a seemingly simple yet profoundly advanced solution: the copper spot self-adhesive explosive certificate label. More than just a sticker, it's a convergence point between physical durability and digital intelligence, engineered to withstand the harshest conditions while ensuring continuous compliance oversight.

The Science Behind the Spark: Why Copper?

At first glance, the metallic copper dot at the label’s center may appear decorative. In reality, it’s a carefully chosen material manifestation of reliability. Copper offers exceptional electrical conductivity and natural corrosion resistance—critical traits in environments where humidity, chemical exposure, and temperature extremes degrade ordinary adhesives and substrates. Combined with a specialized surface treatment that prevents oxidation without compromising reflectivity, this copper element remains legible and functional for years, even under direct UV exposure or sub-zero conditions.

Visible Trust, Invisible Tracking: Dual-Layer Verification in Action

Compliance today demands more than paper trails—it requires real-time, auditable proof. The Shenzhen explosive certificate label serves as both a human-readable badge of approval and a machine-scannable gateway into a digital ecosystem. Technicians scan the QR code or tap via NFC to instantly access device history, inspection logs, and certification validity—all synchronized with cloud-based asset management platforms. From remote mines to urban energy storage units, every interaction creates a timestamped audit trail, transforming passive labels into active guardians of accountability.

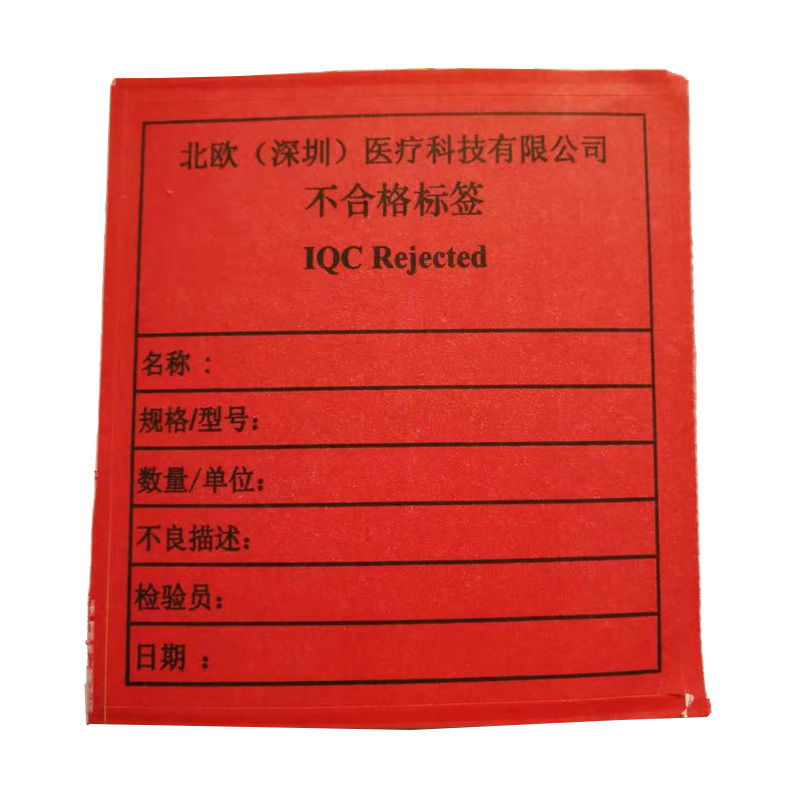

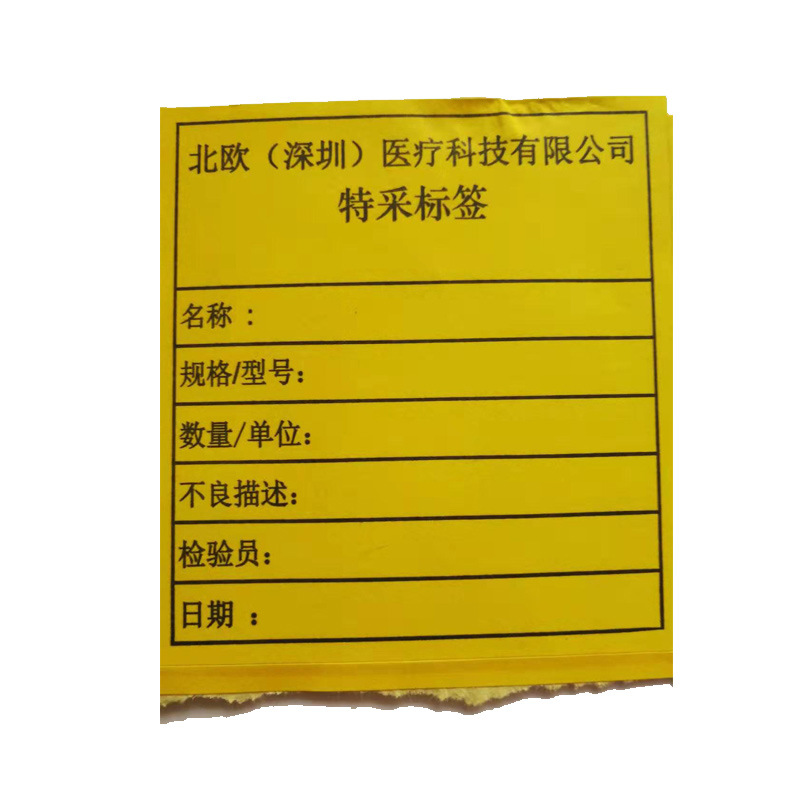

The Psychology of Tamper Resistance: Design That Deters Deception

A key feature lies beneath the surface: an engineered “frangible” structure. Once applied, any attempt to remove the label triggers irreversible micro-fractures in the adhesive layer and substrate, leaving behind a visible “VOID” pattern or broken copper matrix. This isn’t merely forensic—it’s psychological. Knowing that replacement attempts will be immediately evident discourages unauthorized substitutions before they happen. In logistics hubs and maintenance depots alike, this passive defense significantly reduces the risk of counterfeit certifications slipping through audits.

More Than a Label: A Microcosm of Shenzhen’s Smart Manufacturing Ecosystem

This innovation doesn’t exist in isolation. It emerges from Shenzhen’s dense network of electronics manufacturers, IoT developers, and rapid prototyping labs. Local R&D teams iterate quickly based on field feedback, aligning materials and communication protocols with evolving international standards like IECEx and ATEX. The result is not just a product, but a scalable model of trust—one where localized production enables global compliance, and agility meets regulation.

From Oil Rigs to EV Batteries: One Label, Infinite Applications

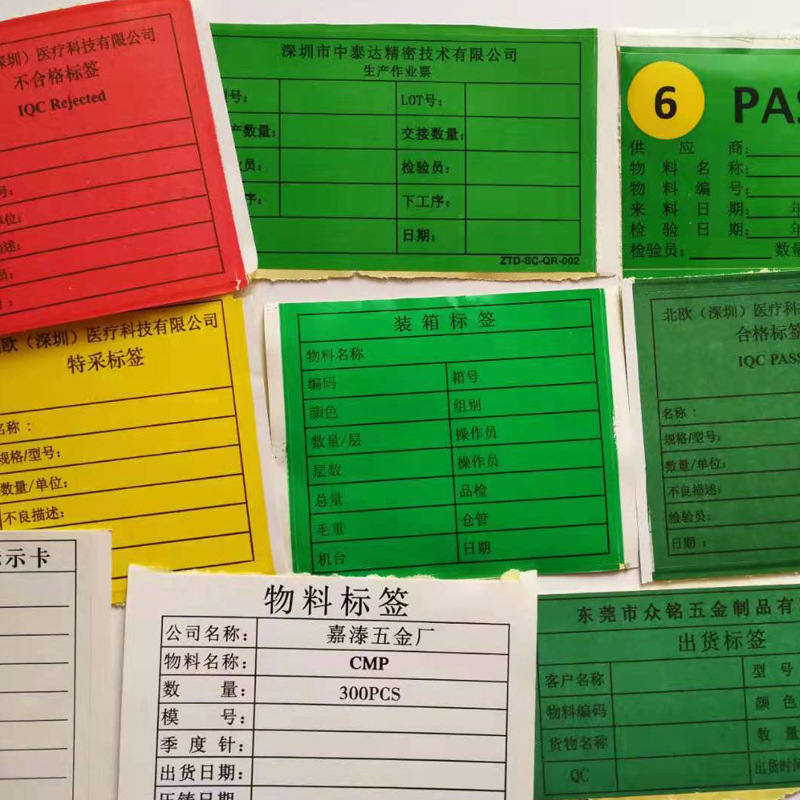

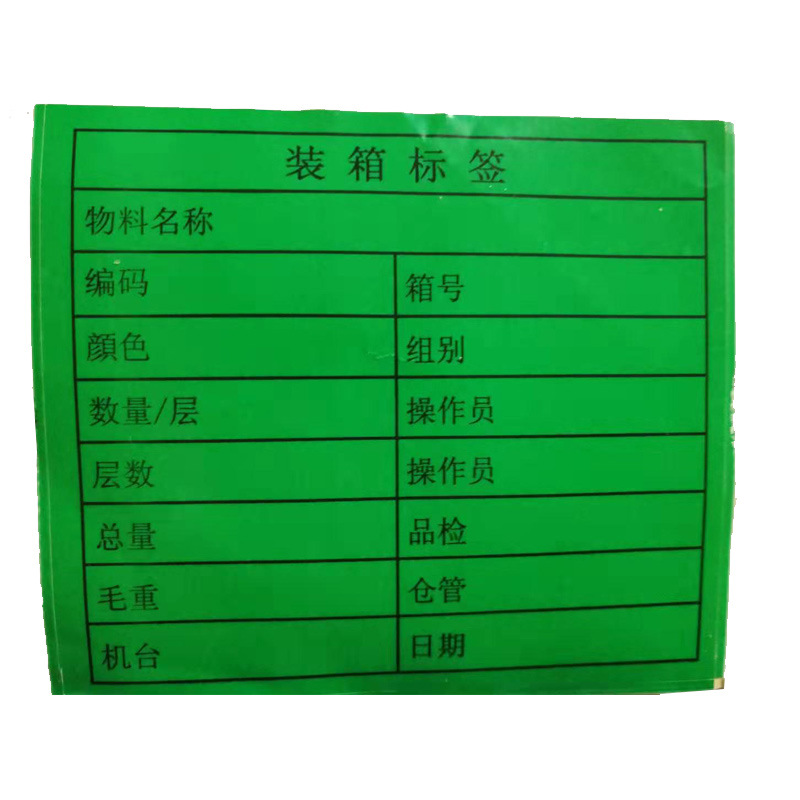

Whether embedded on explosion-proof enclosures in petrochemical plants, affixed to mining ventilation controls, or certifying battery management systems in next-gen energy storage, the core design adapts seamlessly. Customizable layouts accommodate regional regulatory symbols, bilingual text, and even brand-specific color schemes—proving that standardization and flexibility aren't mutually exclusive when intelligent design leads the way.

The Future Speaks: Toward Active, Responsive Labels

What if your certification label could warn you before failure occurs? Emerging prototypes integrate miniature sensors—monitoring temperature spikes, vibration anomalies, or seal integrity. Paired with low-energy Bluetooth or LoRa transmission, these next-generation stickers won’t just prove past compliance; they’ll predict future risks, turning static identifiers into proactive sentinels across smart factories and无人巡检 (unmanned inspection) zones.

Making Compliance Effortless: Where Security Meets Simplicity

The greatest strength of this technology may lie in its invisibility during daily operations. With strong acrylic adhesives that bond securely to metal, plastic, and composite surfaces, installation takes seconds. Once set, the label endures washdowns, abrasion, and thermal cycling—freeing engineers to focus on critical tasks instead of re-labeling or manual record checks. True safety integration means compliance fades into the background, working silently until needed.

Is Trust Something You Can Stick On?

In an age of automation and decentralized oversight, the intersection of physical presence and digital identity has become the new cornerstone of industrial trust. The Shenzhen explosive certificate label represents more than regulatory adherence—it symbolizes a shift toward intelligent infrastructure where every component carries its own verified story. Perhaps the most powerful security measure isn’t surveillance, but visibility. And sometimes, all it takes is a small copper dot to make the invisible, undeniable.