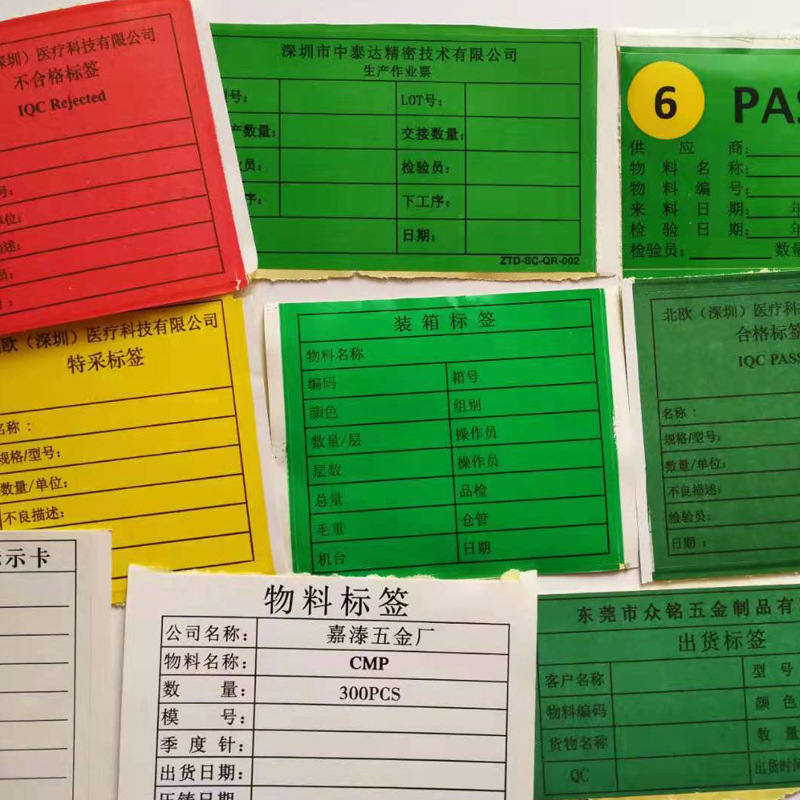

A close-up of the Shenzhen explosive certificate label applied to high-risk industrial equipment—durable, visible, and trusted.

When Compliance Becomes Competitive: The Industrial Trust Revolution Behind a Single Sticker

In an era where regulatory audits can make or break supply chain partnerships, compliance is no longer just about passing inspections—it's about building trust. The Shenzhen Explosive Certificate Label represents a paradigm shift from passive documentation to active assurance. No longer treated as an afterthought or a bureaucratic formality, this copper self-adhesive digital sticker transforms safety certification into a visible, verifiable, and valuable asset. In industries handling hazardous materials—from petrochemicals to advanced battery systems—this label isn’t merely a marker of approval; it’s a declaration of operational integrity.

What sets it apart is its role in the Industry 4.0 landscape. While digital twins and cloud-based monitoring dominate headlines, the physical world still demands physical proof. This sticker bridges the gap—offering machine-readable data while remaining instantly recognizable to human inspectors. It proves that even in a hyper-connected age, tactile, tamper-evident identifiers remain indispensable for real-world safety verification.

The metallic luster of the copper substrate isn't just aesthetic—it's engineered for performance and durability.

The Science Beneath the Shine: Why Copper Makes All the Difference

Beneath its sleek, reflective surface lies a carefully engineered composite structure. The use of copper isn’t arbitrary; it’s a strategic choice rooted in material science. Copper offers exceptional electrical conductivity—critical in environments prone to static discharge—while also providing superior resistance to corrosion, UV degradation, and chemical exposure. These properties ensure the label remains intact and legible even after years of service in harsh industrial conditions.

Digital printing technology enables micro-precision in information embedding, allowing for QR codes, batch numbers, expiration dates, and certification IDs to be printed with razor-sharp clarity. Each sticker is serialized and traceable, creating a permanent digital fingerprint tied to the device it protects. Meanwhile, the self-adhesive backing undergoes rigorous temperature testing, maintaining adhesion from sub-zero cold storage at -40°C to sweltering production floors exceeding 80°C. Whether mounted on a cryogenic valve or a reactor vessel in a tropical facility, the bond stays secure.

An inspector verifies compliance in seconds—proof that clarity accelerates safety.

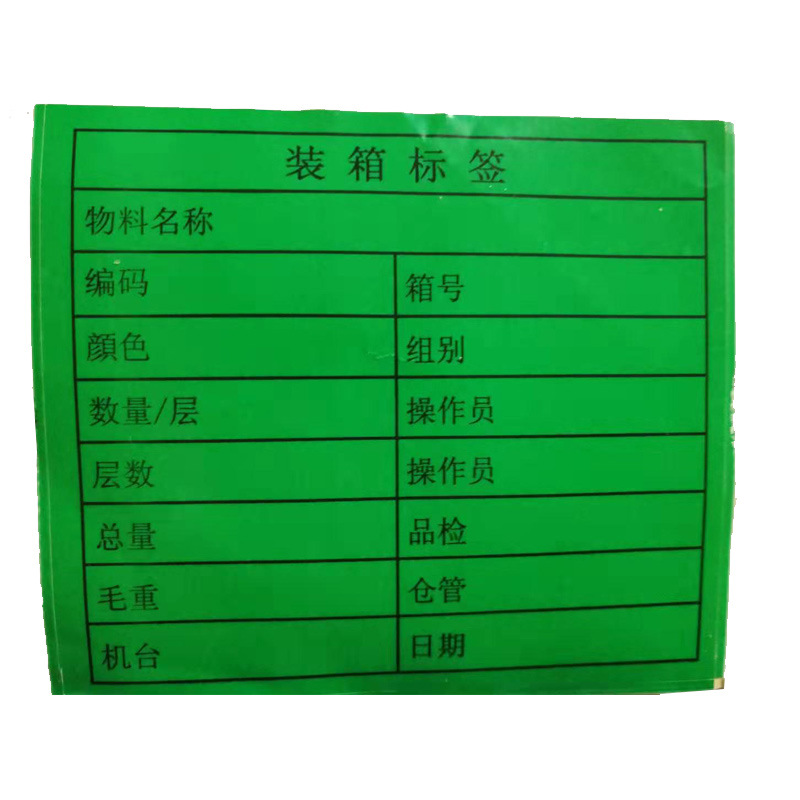

Silent Authority: Speaking Volumes Without Saying a Word

To a trained inspector, this label communicates volumes in under three seconds. Its design follows cognitive ergonomics: high-contrast typography, internationally recognized symbols, and strategically placed scannable elements allow instant recognition. There’s no need to dig through binders or request digital files—the evidence of qualification is right there, on the equipment surface.

One logistics company reported reducing inspection stoppages by 68% after switching to these standardized labels across their fleet of hazardous cargo containers. In multilingual settings—such as global shipping hubs or multinational manufacturing sites—the universal iconography eliminates language barriers, ensuring consistent understanding regardless of nationality or training background.

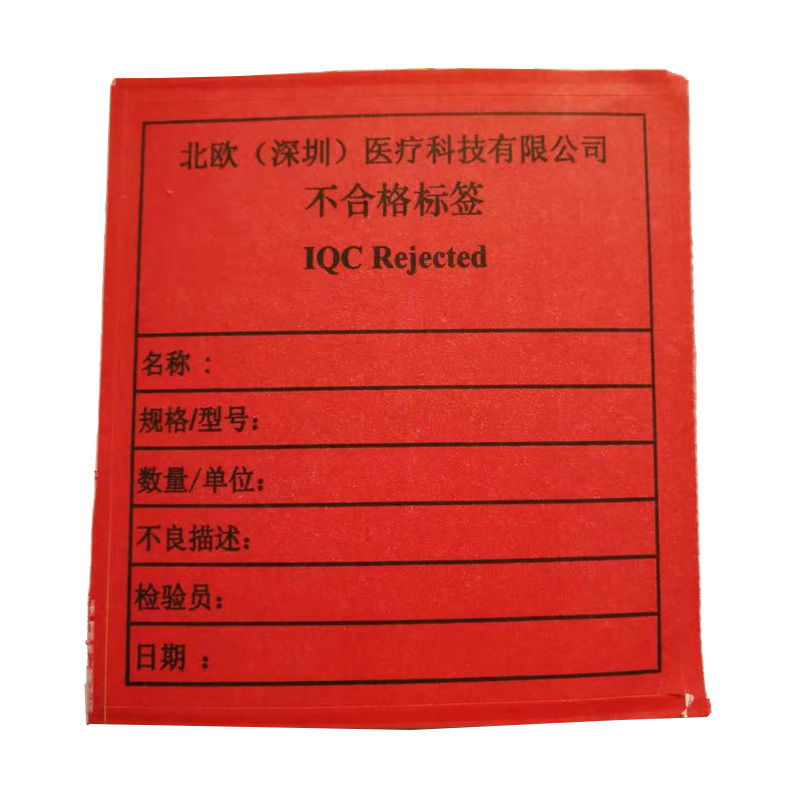

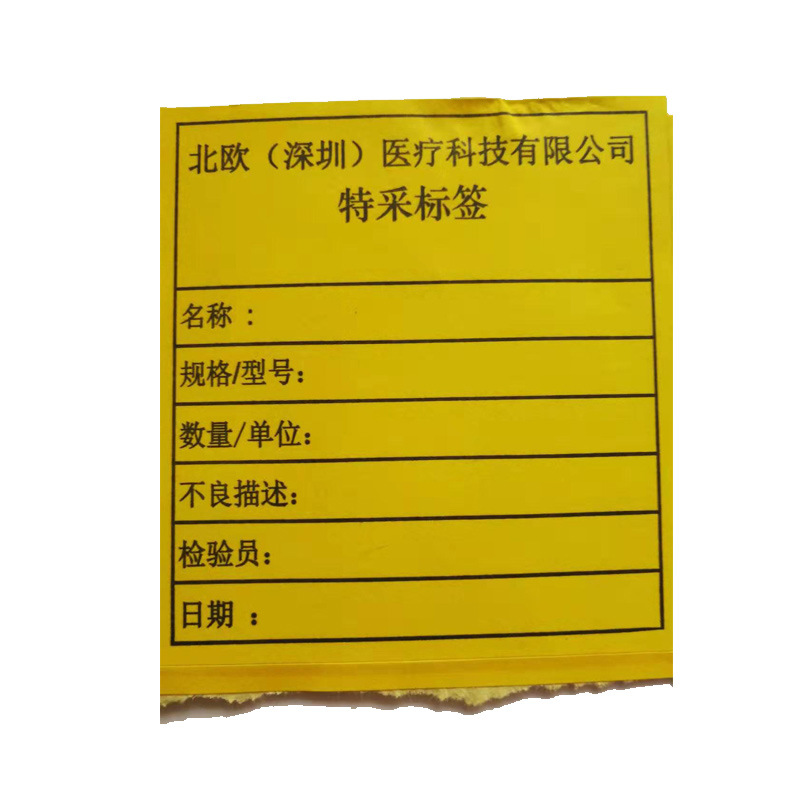

Passive Tag, Active Guardian: Securing the Entire Supply Chain

This sticker doesn’t retire after factory certification. It travels with the equipment, serving as a continuous witness throughout warehousing, transportation, and end-user deployment. Through spot-labeling practices—applying stickers at critical junctures like valves, connectors, or battery enclosures—companies establish a clear chain of custody. If an issue arises, investigators can pinpoint exactly when and where each component was last verified.

The anti-tamper design is equally vital. Attempting to remove the sticker triggers a micro-fragmentation layer, leaving behind a visible “VOID” pattern. This forensic-level protection prevents fraudulent reuse and ensures accountability at every handover point.

Once removed, the label leaves a clear VOID mark—making tampering immediately obvious.

Turning Compliance Into Efficiency: The Hidden Productivity Boost

Far from being another administrative burden, this sticker streamlines operations. By replacing stacks of paper certificates with a single, durable digital tag, companies accelerate audit readiness and reduce document management costs. A technician can apply over 300 labels per hour, enabling rapid retrofitting of legacy equipment fleets.

Moreover, integration with enterprise systems is seamless. Scanning the QR code can automatically log compliance status into ERP or EHS platforms, triggering alerts for renewal or flagging expired certifications—turning passive labeling into proactive risk management.

Where You’d Least Expect It: From Batteries to Polar Research Stations

Originally designed for explosive storage containers, the application scope has expanded dramatically. Today, you’ll find these stickers on lithium-ion battery modules in EV assembly lines, pressure relief valves in offshore rigs, and even hydrogen fuel cells in clean energy projects. For overseas deployments, the label can be customized to meet EU ATEX, US DOT, or Chinese GB standards—all within the same production run.

A notable case involved a polar research team equipping scientific instruments with a modified version rated for -60°C operation. The copper substrate remained flexible, and the adhesive held firm despite extreme thermal cycling—a testament to its engineering resilience.

Engineered for extremes: a specialized variant used in arctic research missions.

The Future Is Already Labeled: What Comes Next?

Today’s sticker may evolve into tomorrow’s smart sensor. Engineers are exploring embedded NFC chips that transmit real-time condition data, or thermochromic inks that change color if exposed to unsafe temperatures. Imagine a label that doesn’t just prove past compliance but actively warns of emerging risks.

As Shenzhen emerges as a global hub for safety innovation, these labels symbolize more than technical excellence—they represent China’s growing influence in shaping international safety norms. Every sticker affixed is a small act of standardization, contributing to a safer, more transparent industrial world.

What Are You Really Investing In?

Choosing the Shenzhen Explosive Certificate Label isn’t just about meeting regulations—it’s about investing in brand credibility, operational efficiency, and workplace culture. It signals to clients, regulators, and employees alike that your organization treats safety not as a checkbox, but as a core value. With minimal failure rates and near-perfect inspection pass rates, the long-term savings in downtime, fines, and reputational risk are substantial. In the quiet permanence of a copper sticker, you’re not buying compliance—you’re purchasing peace of mind.